Reciprocating Piston Compressor Kits

- Home

- Reciprocating Piston Compressor Kits

Piston

- All Pistons are manufactured by graded cast iron & aluminium alloys with perfect machining. We can supply as per specifications, drawings or sample of customer’s requirement.

- Pistons are available ready stocks for Aircooled compressors, watercooled compressors, Lubricated type & Non Lubricated type of units.

- All pistons are available with original specifications, dimensions, material of constructions with reliability & competitive price with guarantee of performance

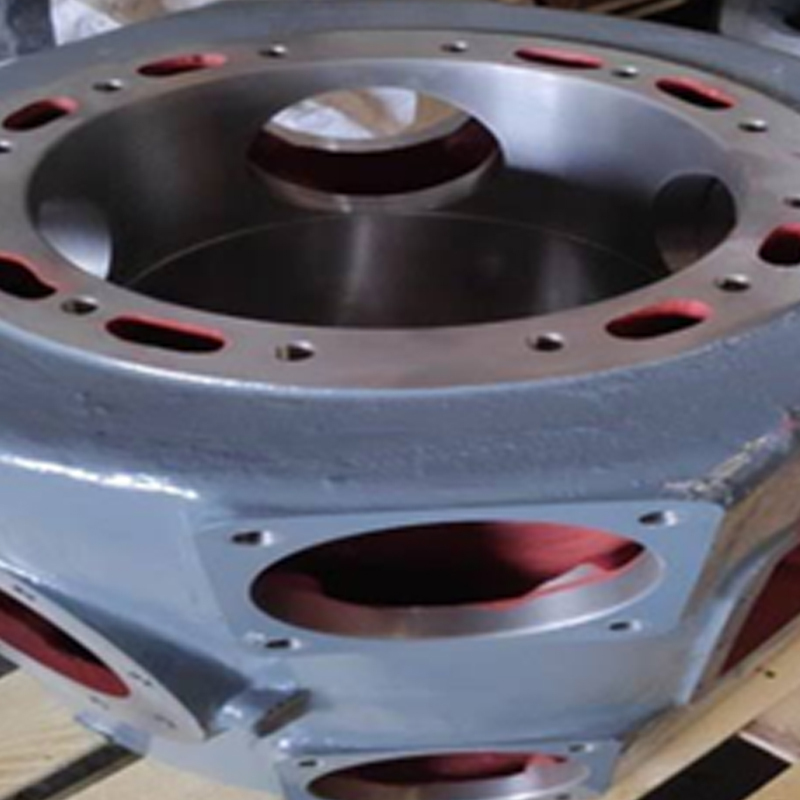

Cylinder

- Cylinders are manufactured by graded cast iron with OEM specifications and dimensions. Cylinders are available in all range for Aircooled and watercooled compressors.

- Cylinders are perfectly bored & honed on vertical boring machine and honing machine with all correct & permissible tolerances. Top/Bottom surfaces are duly ground & drilled with proper fixtures to ensure proper assembly with related parts.

- The length & bore of cylinder is properly maintained as per OEM for correct stroke & flow of Air/Gas & performance of unit

Connecting Rods

- Connecting rods are available in MOC of Aluminium, Leaded bronze, SG Iron& Forging.Connecting rods are available in MOC of Aluminium, Leaded bronze, SG Iron& Forging.

- All the Connecting rods are machined on both the sides. Centre distance between big end & small end is maintained for perfect straightness & perfect boring of big end & small end

- Big end & small end of connecting rods are perfectly bored so as to match original clearances with steel bush for Air cooled unit & aluminium / Bronze floating bushes for water cooled unit

- The above Connecting Rods are available ex-stock & ready for shipment in case of urgency.

- The forged connecting rods are drilled internally perfect to maintain lubrication & oil pressure of unit

Crank Shafts

- Crank shafts are available for both the type of compressor that is Air cooled & Water cooled unit.

- Crank shaft for Air cooled compressors rotates on heavy duty ball Bearings which are hydraulic pressed with axial alignment. These Crank shaft are dynamic balanced for vibration free working of unit & properly drilled for mounting of centrifugal unloaders to release pressurised Air / Gas from Intercoolers during unload position.

- Forged heavy duty Crank shafts are for water cooled heavy duty compressors. These crank shaft are machined and ground on Main Bearing Journal & crank pin Journal by maintaining diametral tolerance and axial tolerance perfectly with main Bearing bushing & crank pin bushing. Also Internally perfectly drilled for oil path for proper lubrication & to maintain oil pressure.

Crank Pin Bush & Bearing

Steel bushing are used in Air Cooled compressors which is readily available for immediate shipment. The same is properly heat treated, maintained tolerances with internal & external grinding and smooth& shining surface. Internal surface will match the dimension of crank pin with easy hand press sliding & external surface with big end of connecting rod for easy assembly & for long life.

These Main Bearing Bushing & Crank Pin Bushing are full floating bearing bush & are used on forged crankshaft for water cooled unit. Our aluminium Main Bearing bush is in one piece with axial cut and are capable of carrying both radial & thrust load. Crank pin bush (two halves) Is a precision bushing which requires no adjustment. The above bearing Bush are made from perfect composition with aluminium ingots, heat treated & complete machined with groove in center & drilled for making oil film for perfect lubrication & maintaining correct oil pressure.

Channel Valves

Crosshead & Pin

Finger ,Concerntric , Assembly Valve

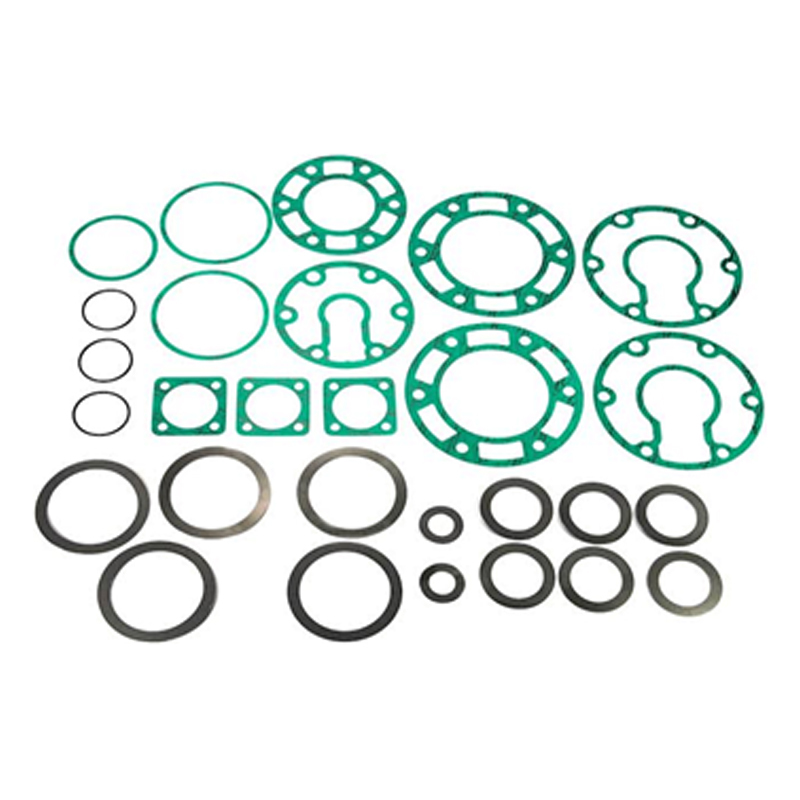

‘O’ Rings/ Gaskets & Oil seals

- Available ready stock in various grades.

- For lubricated compressor individual cast iron piston ring with 45 degree Angle cut / glass filled PTFE Piston ring available ex-stock. Our piston rings are having perfect roundness & spring tension as per the applications, customer’s requirement & long life.

- For Non lubricated unit Piston Rings & Wearing Rings (Guide Rings) are available with carbon filled PTFE, Bronze filled PTFE & thermoplastics.

- Unloader piston rings are also available in glass filled PTFE & Bronze Metallic rings.

- We supply any type of Piston Rings & Guide Rings with MOC cast iron, PTFE, thermoplastic in any size as per specifications ,drawings, sample provided by customer.

Air Filter / Oil Filters

Piston Rod / Oil Scrapper Rings / Packing Rings

- Piston Rods are of different size for different models are available ready stock.

- Our Piston Rods are Heat treated to the specification so as to meet mechanical properties & tensile strength.

- Our Piston Rods are ground to close finish, so as to increase the life of of Oil Scrapper Rings & packing rings.

- Plasma coated Piston Rods can be arranged as per the requirement & Specification of customer’s requirements.

- Having fine threads with close pitch on both end of Piston rod ( crosshead side / piston side)to ensure better looking & Top / Bottom clearance.

- Oil Scrapper Rings are available in different MOC, i.e. Individual graded cast iron,Bronze, glass filled PTFE, with perfect roundness, inner grooved & drilled to wipe oil from piston rod & with S.S. garter spring with proper tension.

- Ring & Spring Packing sets MOC can vary depending upon applications. The Packing Rings sets are available in metallic segment, carbon filled PTFE, Bronze filled PTFE, glass filled PTFE; with CI backup rings. They are readily available suitable for different diameter of piston rods. It is also available in 3 piece, 6 piece, Segmental, Radial cut, Tangential cut segment with garter spring with proper tension so as it seal the pressure of Air/Gas & long lasts. Ring & spring packing set for High pressure unit with metallic back up rings are also available ready stock for immediate shipments.

Oil for Air compressors

Compressors are expected to function for long service intervals without maintenance. It is essential to select the right lubricating oil for the compressed medium, which can be air, process gas or a refrigerant. Our product range is proven for compressors of all types. They minimise wear and extend service intervals for higher compressor availability.

Our oil offers a lot of benefits when compared to the mineral oil and other competitor’s synthetic oil, as mentioned below

- Reduced down time costs.

- Increased Compressor availability.

- Reduced spare parts costs for oil, filters and separators.

- Less strain on environment and resources due to lower energy consumption and lower disposal quantities.

- Reduces friction in the compressor and offers a better gap sealing effect.

- Low pour points.

- Longer oil life

- Improved oxidation protection

- Reduced power consumption