Oil free screw compressor Air End Reconditioning

- Home

- Oil free screw compressor Air End Reconditioning

Atlas Copco Z element Overhaul

- Sending your old air end (element) to us for refurbishment couldn’t be simpler…

- We stock refurbished elements from stage 1 to 6 and as well as competitive priced refurbished air ends for oil free compressors we stock stages 1 to 6 NON OEM NEW elements..

- Providing your air end turns we can normally fully restore the air end to full working condition like new with a TEST certificate to prove its condition..

We offer a ‘green’ service to overhaul your Atlas Copco bearing lifetime expired oil frecompressor element.

Just because its reached its bearing life or seals leaking doesn’t mean the whole air end has to be replaced with a NEW air end.

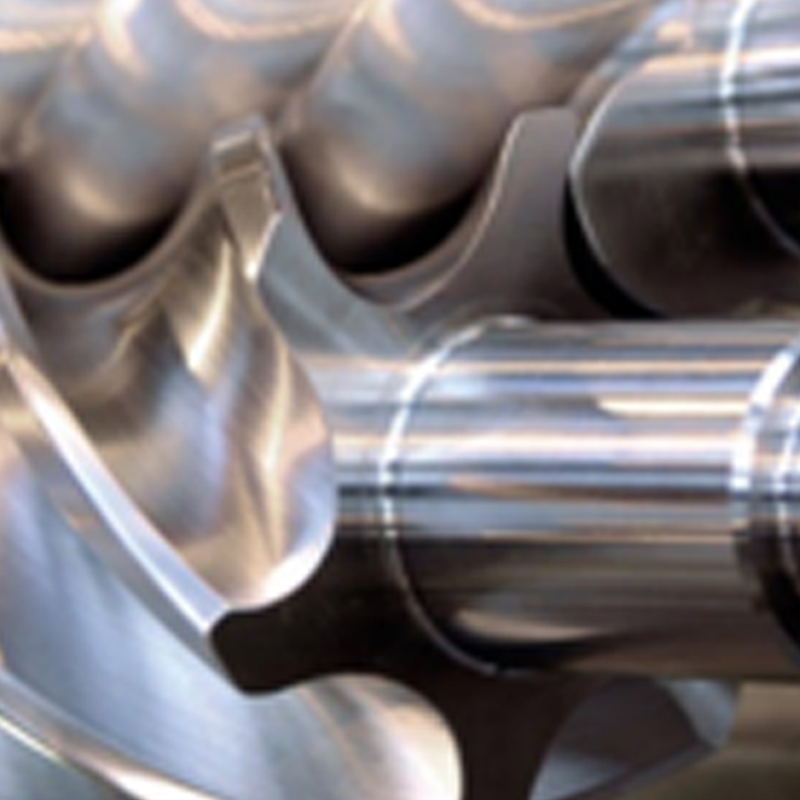

Refurbishing your existing Atlas Copco oil free compressor Low and High pressure element stages is second nature to our company.

Seals & Bearings

With refurbished elements sold each year and less than 3% warranty claims . we have a proven reliable product backed up with a standard 12 month warranty extendable up to 5 years with a service agreement. Our company has produced our own seals for both the NEW NON OEM elements and the refurbished product. The quality of materials and precision engineering ensures the seals we use are robust enough to surpass 40,000 hours run and dependant on site environment circumstances surpass 50,000 hours plus in certain cases.

Casting Inspections

All castings are shot blasted after tear down and fully inspected and pressure tested, Casting that have wear inconsistent with normal wear Water cavity erosion, Casting Surface damage are rejected for refurbish.

Normally Atlas Copco castings have a 2 or 3rd time refurbish lifetime providing the water quality has been closed circuit loop and ambient conditions and filtration have been maintained to OEM service standards.

Our castings are coated both in our lining coating and water cavity coatings before being finished with a high quality paint to finish

Element Testing

All refurbished and NEW air ends are tested before shipping to customers and a test certificate produced of the efficiency of the refurbished element accompanies the element to its final destination.

Warranty begins when the air end is installed*

‘ Don’t just replace, refurbish’

End users or Distributors must have fulfilled the Quality Air solution’s criteria for warranty purposes

Our Finished Product

Our products are all carefully package in solid crates for overseas shipping and the whole process of shipping and return of your old element is carried out by our trained logistics team.

Please note for an efficient lowest cost refurbish program to work we must request customers return elements timely and in turning condition otherwise a 30% Non Return Charge is applied (NRC)

For further explanations of our products, NRC, and warranty please contact our supply department now and we will endeavour to answer all your questions or concern